With the planet’s population expected to reach nearly 10 billion by 2050, an innovative approach is to require that both the production and processing of agricultural products and food meet the needs of agricultural and food products.

One of the biggest challenges remains the supply of safe agricultural products and foods to meet global demand. Nearly one-third of the world’s food production for people is wasted along with the food production, processing, and supply chain.

Intelligent solutions need to be developed for sustainable food and agricultural consumption patterns with global food security. An environmentally friendly intervention strategy to protect food crops or food products from decay or pests, resulting in reduced losses and / or extended shelf life, is an important part of global food security.

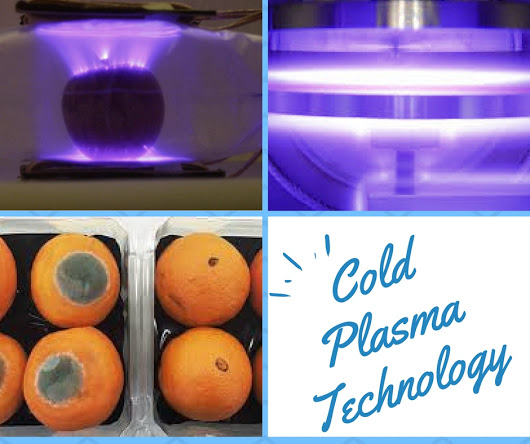

The latest research results show that among the new methods of improving the bacterial and chemical safety of fresh products, cold plasma is the most effective and has great potential application for the decontamination of agricultural products and fresh food.

1. Organizational Capacity to implement

Professor Shi Nguyen-Kuok is a leading expert in the plasma field, Plasma Laboratory of Moscow Power Engineering Institute has accomplished great research in application deployment plasma technology cold in agriculture and food safety. Experts of VinIT Institute of Technology have been conducting this technology research for many years.

2. Objectives

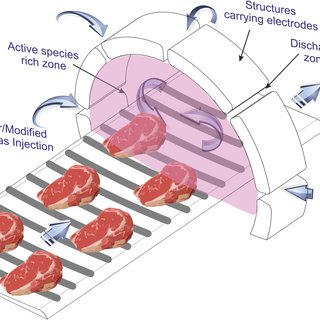

- Designing and manufacturing cold plasma equipment system for processing and preserving agricultural products, fruits and vegetables;

- Establish the technological process for processing and preserving agricultural products, fruits, and vegetables.

3. S&T contents need to be resolved

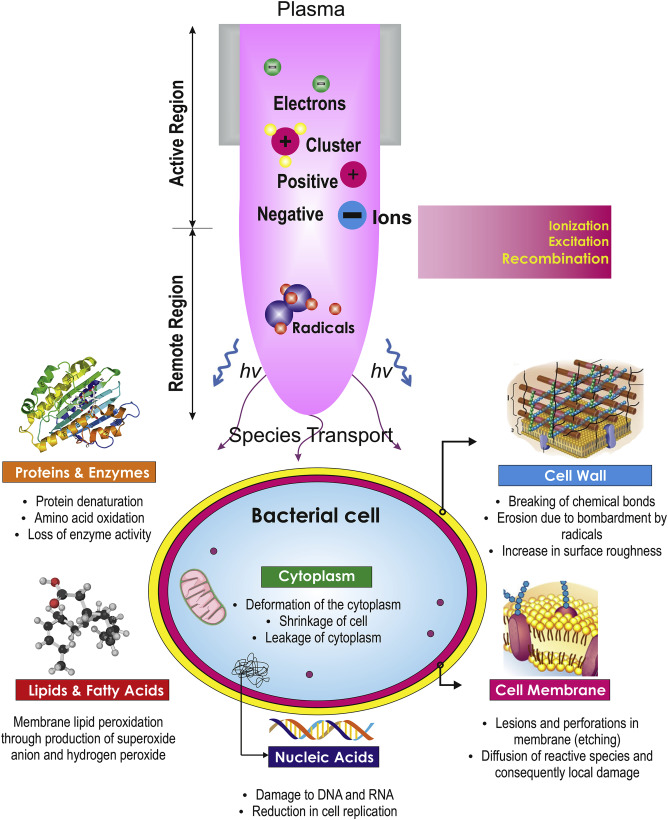

- The effect of cold plasma flow on proteins/enzymes, plasma effect on lipids, cold plasma impact on carbohydrates, interaction during cold plasma exposure, radical decontamination and protective effects, effects cold plasma to the functional properties of the food system;

- Assessing the quality of food processed by cold plasma, physical quality, chemical quality, sensory properties;

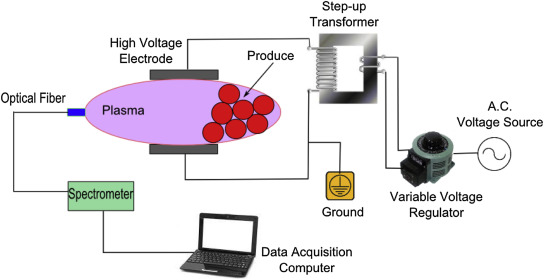

- Research the physical and chemical reaction process in creating cold plasma;

- Studying the mechanism of the effects of the cold plasma on the organism, the combined effect of the bactericidal components from the molecular surface layer on the organism;

- Designing and manufacturing prototypes of cold plasma devices for preserving fruits and vegetables (experimental);

- Clinical trials, quality assessment for equipment;

- Completing the technology of manufacturing cold plasma devices;

- Designing and manufacturing prototypes of cold plasma devices for preserving agricultural products (experiments);

- Clinical trials of cold plasma equipment used in the processing of agricultural products;

- Establish the technological process for manufacturing equipment and explain how to use cold plasma devices for processing agricultural products and preserving food.

4. Expected product creation

- Report on the research results of the mechanism of cold plasma effect on organisms, bacteria, etc.;

- The design drawing some high-voltage cold plasma generator (5-15 kV, inverters, power supply, gas);

- Intermediate products: cold plasma equipment including processing chamber, matrix table of cold plasma generator, the control cabinet for processing fruit and vegetables;

- 01 System of cold plasma equipment used for processing fruits and vegetables, including cold plasma equipment and auxiliary equipment (sorting, packaging, etc.);

- 01 System of cold plasma equipment used for processing agricultural products, including cold plasma equipment and auxiliary equipment (classification, packaging, etc.);

- Report on clinical trial results, worth the quality for the cold plasma equipment;

- Technological process of manufacturing cold plasma equipment used in agricultural products and foods;

- Registration of 1-2 patents.

5. Applicability

High wide range of applications in harvesting, processing, preserving and trading establishments of agricultural products and foodstuffs, fruits and vegetables. Cold plasma sterilization technology has almost all the conditions that an ideal sterilization method should have:

- Save time: Compared with autoclave and dry heat sterilization, the disinfection time is short;

- Low cost: Much more effective than other chemical and thermal disinfection methods;

- Normal temperature: Disinfection temperature is 35 to 45 ° C. Compared with chemical sterilization using 1,2-ethylene oxide as the main ingredient, the operating temperature is low and can be widely used to disinfect different types of materials and articles;

- Safety: Using automatic touch panel, easy to operate, no need for high temperature and high pressure, simple installation and commissioning, safe use.

6. Effective

Socio-economic efficiency: Cold plasma technology is the most advanced today, the success of the project is a breakthrough in food preservation technology, allowing extended shelf life of the product many times, improve the value of products; thus promoting the development of fruit and vegetable production agriculture, promoting the development of food processing and preservation technologies; creating many jobs, with great significance in protecting the environment, improving living conditions, increasing people’s health and bringing benefits to the whole society.

The system of agricultural and food processing equipment can be applied at all harvesting, processing and storage facilities.