This paper describes the different sterilization methods and technologies currently available in today’s medical equipment sterilization market. Each method is reviewed in detail and major differences amongst each are highlighted. Focus is given to the more common sterilization methods used and/or available for medical equipment in hospitals and clinics today.

Common Sterilization Methods

Common High Temperature/Pressure Sterilization

A. Steam Autoclave

Steam autoclave is the oldest, safest, and most cost effective method of sterilization in the medical equipment industry. The steam reaches 121-148°C (250-300°F) in the pressure chamber at 15 P.S.I. The sterilization period is dependent on the temperature and size of load and can range from 10-60 minutes.

The common types of steam sterilization cycles are gravity-displacement, which removes air from the chamber by gravity displacement as steam-entering chamber exerts pressure on air; and the pre-vacuum cycle, which removes air by a vacuum pump while steam is simultaneously injected into the chamber. The following summarizes the processing parameters for each cycle:

- Configuration: Gravity Displacement

- Temperature: 121-123 °C (250-254 °F)

- Time: 15 – 30 minutes

Configurable cycles allow the user to customize the sterilization cycle for items such as hard items, wrapped items, liquids in vented containers, waste, and glassware.

The fastest steam sterilization used is flash sterilization and it can be accomplished using either gravity-displacement, or pre-vacuum cycles. It is generally a high-speed steam sterilization of an unwrapped instrument or device for 3 to 10 minutes in 132°C saturated steam. This type of sterilization is only intended for use in hospital operating rooms for urgently needed equipment.

In the steam autoclave process, microorganisms are killed by heat, and this is accelerated by the addition of moisture. Steam by itself is not sufficient for sterilization, and pressure that is greater than atmospheric is needed to increase the temperature of steam for thermal destruction of microbial life.

Steam, for a specified time at required temperature, must penetrate every fiber and reach every surface of items to be sterilized. When steam enters the sterilization chamber under pressure:

- It condenses upon contact with cold items

- This condensation frees heat, simultaneously heating and wetting all items in the load, thus providing heat and moisture

Any living thing will be killed when exposed to saturated steam at 120°C (250°F) longer than 15 minutes. As temperature is increased, time may be decreased. A minimum temperature-time relationship must be maintained throughout all portions of load to obtain effective sterilization. At the end of the cycle, re-evaporation of water condensate must effectively dry contents of the load to maintain sterility.

Application:

Steam autoclave is used mostly for surgical instruments. This method is not well suited for heat sensitive materials and instruments. Many surgical instruments are not designed to withstand prolonged heat and moisture of the steam sterilization process. This leads to alternative sterilization categories: chemical sterilization and radiation sterilization, which allow heat and moisture sensitive materials to be sterilized.

Common Chemical Sterilization

A. Ethylene Oxide (EtO) Gas

Ethylene Oxide gas was introduced in the 1950’s, and it is an effective, low temperature chemical sterilization method. It also takes longer than steam sterilization, typically, 16-18 hours for a complete cycle. Temperatures reached during sterilization are usually in the 50-60°C range.

Ethylene oxide (EtO) is a chemical agent that kills microorganisms, including spores. EtO gas must have direct contact with microorganisms on the items to be sterilized. Due to EtO being highly flammable and explosive in air, it must be used in an explosion-proof sterilizing chamber in a controlled environment.

Items sterilized by this process must be packaged with wraps and be aerated. The aeration time may be long and is needed to make sterilized items safe for handling and patient use.

Note: There are also gas sterilizers available that use a mixture of EtO with carbon dioxide or chlorofluorocarbon (CFC) to represent it as nonflammable for use in healthcare facilities. In addition to safety concerns, this type of sterilization process requires an even longer aeration process compared to pure EtO sterilization.

In general, EtO gas is a reliable and safe agent for sterilization when handled properly. OSHA[ also has special handling guidelines for Ethylene Oxide.

Application:

EtO is used to sterilize items that are heat or moisture sensitive. Disadvantages of EtO gas are that it can leave toxic residues on sterilized items and it possesses several physical and health hazards to personnel and patients that merit special attention. Since EtO poses several health hazards, there are currently two alternative technologies that are currently available: Sterrad®, a plasma phase hydrogen peroxide-based sterilizing agent and Steris, a per acetic acid based technology.

B. Sterrad® – Low Temperature Hydrogen Peroxide Plasma

(A Johnson & Johnson product)

Introduction to Low Temperature Plasma:

Low temperature plasma sterilization was introduced to fill the gap between autoclave: high temperature steam sterilization (safest, fastest and least expensive) and EtO gas sterilization, which leaves toxic residuals. It is a low temperature, non-toxic, but fairly expensive sterilization method. In this process, hydrogen peroxide is activated to create a reactive plasma or vapor.

Note: Plasma is ionized gas made up of ions and electro ns and is distinguishable from solid, liquid, or gas. Plasma is often referred to as the fourth state of matter.

The Sterrad system is a Hydrogen Peroxide Gas Plasma Sterilization system with an operating temperature range of 45-50°C. Operating cycle times range from 45-70 minutes, depending on size of system.

This sterilization system uses a combination of hydrogen peroxide and low temperature gas plasma to quickly sterilize most medical instruments and materials without leaving any toxic residues. Hydrogen peroxide is a known anti- microbial agent that is capable of inactivating resistant bacterial spores.[ Sterilization by this method occurs in a low moisture environment.

The Hydrogen Peroxide Plasma Process using Sterrad: The process consists of two consecutive and equal sterilization phases.

Vacuum / Pre plasma stage:

- When a low pressure is achieved in the vacuum stage, low temperature air plasma is generated. This helps in removing residual moisture from the chamber. The system is then vented to atmospheric pressure at the end of this stage;

- Pressure in chamber is reduced and an aqueous solution of hydrogen peroxide is injected and vaporized into chamber;

- The hydrogen peroxide diffuses throughout the chamber, surrounds the items to be sterilized, and starts the inactivation of the microorganisms;

- After the pressure is reduced, applying radio frequency (RF) energy creates an electric field and thus forms low temperature plasma;

- Free radicals are generated in the plasma by breaking apart the hydrogen peroxide vapor. Once the activated components react with the organisms and kill them, they lose their high energy and re-combine to form oxygen, water vapor, and nontoxic by-products;

- This is half of the total sterilization process. The other half of the cycle is completed by repeating the above sterilization steps;

- At the completion of the second half cycle, the source of RF energy is turned off, vacuum is released, and chamber is returned back to atmospheric pressure by introduction of filtered air.

Application: This system is best suited to sterilize heat sensitive medical equipment such as endoscopic equipment. With two systems, sterrad provides sterilization solutions for both smaller and larger applications.

C. Steris System 1® Sterile Processing System

(A steris Corporation product)

The steris system 1 is another, more common, low temperature sterile processing system. It uses the steris 20 sterilant Concentrate that combines peracetic acid, a chemical biocidal agent, and a proprietary anti-corrosion formulation to kill micro- organisms at low temperature.[2] The process is achieved at a temperature of 50-56°C.

The steris 20TM Sterilant Concentrate is mixed with sterile water to create the solution that flows into the sterilization chamber. The sterilization time is 12 minutes. This is followed by repetitive sterile water rinses to complete the process. The entire process is completed in less than 30 minutes for a standard cycle.

Peracetic acid, by itself, is an oxidant and disinfecting agent for liquid immersion. It maintains its effectiveness when high levels of organic debris are present. It is an acetic acid plus an extra oxygen atom that reacts with most cellular components to destroy cells.

Application: Only immersible instruments can be used with this method, and only a few instruments can be sterilized at one time. No packaging required.

D・ Cidex® OPA Solution – Alternative to Glutaraldehyde

(A Johnson & Johnson product)

Cidex® OPA solution is a High Level Disinfectant (HLD) for use in reprocessing heat sensitive medical devices. Cidex OPA solution provides high-level disinfection in 12 minutes at room temperature (20°C) and is particularly active against mycobacteria, including glutaraldehyde-resistant strains of M. chelonae. CIDEX OPA solution has the broad materials compatibility of glutaraldehyde (but does not contain glutaraldehyde), requires no activation, and has minimal odor. The Cidex OPA solution is replacing Cidex® and Cidex Plus® due to their toxicity concerns.

Application: This solution is frequently used on surgical cameras (endoscopes). The item to be disinfected must be thoroughly cleaned and dried before immersion. After immersion, the item must be rinsed thoroughly with sterile water prior to use.

Common Radiation Sterilization

A. Gamma, Beta Sterilization

Irradiation is an effective sterilization method, but it is limited to commercial use only. The product to be sterilized is exposed to radiation for 10 to 20 hours, depending on the strength of the source. The highest temperatures reached in gamma sterilization are usually 30-40°C. Gamma radiation is popular for sterilizing before shipment and it can be done through the packaging. A dose of 2.5 megarad is generally selected for many items.

Ionizing radiation produces ions by knocking electrons out of atoms. These electrons are knocked out violently, and strike an adjacent atom and either attach themselves to it, or dislodge an electron from the second atom. The result is ionic energy that becomes converted to thermal and chemical energy. This energy kills microorganisms by disruption of the DNA molecule, therefore preventing cellular division and propagation of biologic life.

The principal sources of ionizing radiation are beta particles and gamma rays. Beta particles, free electrons, are transmitted through a high-voltage electron beam from a linear accelerator. These high-energy free electrons will penetrate into matter before being stopped by collisions with other atoms. This means their usefulness in sterilizing an object is limited by the density, thickness of the object and by the energy of the electrons. These free electrons produce their effect by ionizing the atoms they hit, producing secondary electrons that kill microorganisms.

Cobalt 60 is a radioactive isotope capable of breaking down to produce gamma rays. Gamma rays are electromagnetic waves that have the ability to penetrate a much greater distance than beta rays before losing their energy from collision. Because they travel with the speed of light, they must pass through a thickness measuring several feet before making sufficient collisions to lose all of their energy. Cobalt 60 is the most commonly used source for irradiation sterilization.

Application:

The radiation can change the properties of some materials like plastics and have adverse affects on glues or adhesives. As you can see, each of the six common methods discussed above have their advantages and disadvantages.

Other Sterilization Methods

In this section, the other, less common sterilization methods are described. These methods are either existing, being replaced by new sterilization, or are still in development.

Other High Temperature / Pressure Sterilization

A. Dry Heat

This process is conducted at 160-170°C for a minimum of two hours. Due to its high temperatures, its applicable use is limited.

Dry heat in the form of hot air is used primarily to sterilize anhydrous oils, petroleum products, and bulk powders that steam and ethylene oxide gas cannot penetrate. In the absence of moisture, higher temperatures are required than when moisture is present because microorganisms are destroyed through a very slow process of heat absorption by conduction.

Other Chemical Sterilization

A. Glutaraldehyde (Cidex Plus® and Cidex®)

(A Johnson & Johnson product)

Cidex Plus® and Cidex® are two of the brand names for Glutaraldehyde, which has been a known disinfectant in the medical industry. It has been found that these two solutions can provide sterilization after 10 hours of use, but the manufacturer has not verified this claim.•Cidex Plus Solution is a disinfectant that is used to disinfect medical instruments. It is a 3.4% alkaline glutaraldehyde solution, which has tuberculocidal and high- level disinfection capabilities. It achieves high-level disinfection in 20 minutes at 25°C and has up to a 28-day reuse life.

Cidex Activated Dialdehyde Solution is used to disinfect medical instruments and endoscopes. This solution can also be used in an automated reprocessor. (An automated reprocessor is the machine used to disinfect endoscopic and medical devices with a high level disinfectant solution.) It is a 2.4% alkaline glutaraldehyde solution, which has tuberculocidal and high-level disinfection capabilities. It achieves high-level disinfection in 45 minutes at 25°C and has up to a 14-day reuse life.

Both have been used as a cold liquid high-level disinfectant for heat sensitive equipment.

Note: Cidex (glutaraldehyde) products are being withdrawn from the European market due to concerns that it is toxic and harmful to health care staff in hospitals. Also, the U.S. market is requiring glutaraldehyde-free chemical solutions, which led to the formulation of the Cidex OPA solution. Cidex OPA solution is now known as the alternative to glutaraldehyde.

B. VHP® MD Series

(A product of Steris Corporation)

VHP® (Vaporized Hydrogen Peroxide) MD Series Sterilization System for Medical Devices is yet another low temperature sterilization system. It is also a product of Steris Corporation. It is different from the Sterrad system, in that it only uses hydrogen peroxide in vaporized form for sterilization, while the Sterrad system uses vaporized hydrogen peroxide to initiate the sterilization, and then plasma (created by RF energy) to complete the sterilization process.

In the VHP process, hydrogen peroxide vapor is injected into the chamber via a series of pulses to sterilize packaged medical and diagnostic devices. The cycle time is 2 hours and the operating temperature ranges from 3040°C.

Note: This system is large capital equipment that uses hydrogen peroxide as the sterilant and it can sterilize multiple pieces of equipment at one time. On the other hand, Steris Corporation’s other product, the Steris System 1 is a portable tabletop system that uses peracetic acid as the sterilant and it is used to sterilize equipment right before use. The VHP system is relatively new (out on market for a year) and has yet to be commonly used in medical sterilization applications. Like the Sterrad system, it is intended to fill the gap between steam sterilization and EtO gas sterilization.

C. Chlorine Dioxide

Chlorine Dioxide is a chemical liquid sterilization process. The best operating temperature range for this process is 25-30°C, while using low concentrations of ClO2. The process requires 6 hours of contact time to achieve sterilization. The presence of organic matter reduces activity. A processor converts a compound of dilute chlorine gas with sodium chlorite to form ClO2 gas and this gas is then exposed to the equipment in a sterilizing chamber.Note: This alternative may corrode some materials and must be generated on-site. Prehumidification of the ClO2 is also required.

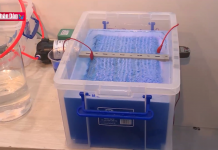

D. Ozone

Ozone sterilizes by oxidation, a process that destroys organic and inorganic matter. It penetrates membrane of cells causing them to explode. In this process, a generator is used to convert oxygen to ozone, as a 6 to 12 percent concentration of ozone continuously flows through the chamber. Ozone penetration is con trolled by vacuum pressure or by adding humidity. After the process is complete, oxygen is allowed to flow through the chamber to purge the ozone. The cycle time may be up to 60 minutes depending on the size of the chamber or load of items to be sterilized.

Ozone is formed by applying electrical energy to the oxygen molecule, which splits some portion of those oxygen molecules in half, into singlets of O. Therefore ozone molecules contain three atoms of oxygen and are unstable. Due to ozone gas being corrosive, and it being able to damage moisture sensitive equipment, there has not been much use of it in the medical industry.

Other Radiation Sterilization

A. E-Beam Radiation

In this process, the E-beam generator delivers a high dose of electrons in a narrow beam at the items to be sterilized. The electrons from the E-beam generator have limited penetrating power, less than gamma radiation. For example, a 10MeV E- beam will penetrate about 5 cm of a unit-density material.

B. X-Ray Sterilization

This is a new developing process that is based on obtaining X-rays through conversion of electron beams. The X-rays produced have the same penetrating properties as the rays produced by Cobalt-60. But with this, treatment is faster, more flexible, and more environmentally friendly.

X-rays offer excellent product penetration in sterilization, thoroughly treating the surface and interior of a product.

Conclusion

There are many sterilization methods available on the market, and it is critical to know that different sterilization methods tailor to different material types, therefore different equipment. Many of the emerging sterilization methods are low temperature based. It is known that steam autoclave is the most widely used, inexpensive, and effective sterilization method that is currently available. Also, historically, many hospitals have relied on EtO- based sterilization systems, but due to environmental and safety concerns, they have been investigating alternatives. Thus, we also discussed the two common, low temperature sterilization alternatives to EtO Gas sterilization: Steris System 1 and Sterrad.

The primary difference between the two: Steris and Sterrad, is that Steris System 1 is a “just in time” technology that requires sterilized items to be immediately used after being removed from the unit. This aspect of Steris makes it impractical in such cases where the need for specific instruments cannot be known ahead of time. Also, Steris Corporation’s VHP MD Series System was also discussed and it is a new low temperature sterilization system that will directly compete with the Sterrad system.

The best, most established, low temperature sterilization method that fills the gap between steam sterilization and EtO gas sterilization, is the hydrogen peroxide plasma technology developed by Sterrad. Although Sterrad is an expensive sterilization method, it is effective and versatile. Also, despite its longer cycle time, the VHP MD Series System has its benefits and will become a more common sterilization system in the future. Out of the six common methods investigated, here are the current rankings of the methods from the most useful to the least useful for medical equipment sterilization:

1. Steam Autoclave

2. Sterrad®

3. Steris System 1®

4. Ethylene Oxide Gas (EtO)

5. Cidex® OPA Solution

6. Gamma Radiation