Plasma gasification technology is an advanced waste treatment technology in the world due to the thorough thermal separation of gas-mixed molecules into simple molecules at a temperature above 2000oC of Plasma and almost no generate toxic gases like Dioxin and Furan.

The advantages of plasma gasification technology:

- The high-temperature gasification technology (T> 2000oC), thoroughly decomposing organic and inorganic wastes, not releasing into the environment toxic substances such as Dioxin and Furan. The content of NOx, SOx and CO2 are smaller than other combustion and gasification technologies due to the high temperature of Plasma and the special structure of Plasma reactors;

- The anaerobic (oxygen-deficient environment) technology: the energy used for the reaction is not based on the C and H oxidation reactions but from Plasma (from electrical energy);

- The highest gasification coefficient (up to 93-95%), so this technology is capable of producing Syngas at an industrial level (CO and H2 content up to 40-50%), suitable for power production;

- The content of ash and dust released into the environment is lowest due to thorough decomposition at high temperatures (T>2000oC ) and due to C and H being fully gasified. Slag components in the form of vitrified can be used to produce concrete slabs (without waste);

- Technology capable of thoroughly handling waste containing impurities (plastic, nylon, sulfur) and poisoning (mercury, cadmium, lead, xenon, cyan, e-waste). Ensuring all the most stringent environmental indicators such as those of G7 and EURO6;

- No need waste classification carefully, just pre-screening waste to remove bricks, stones, metals;

- There is no leachate as rubbish is dried and shredded before being put into the reactor;

- Closed chain, no garbage storage areas, no odor affecting the environment;

- Due to the characteristics of thorough separation and gasification of the Plasma, the simpler air filter components reduce the investment rate for this component from 3-10 times;

- Because there is no need for a landfill and an leachate treatment area, the total area maybe 2-3 times less than other technologies of the same capacity.

The disadvantages of plasma gasification technology:

- Plasma torches use a lot of electrical energy;

- Waste needs to be shredded (size <100 mm) for better gasification;

- Rate investment higher than other technologies results in a longer payback period.

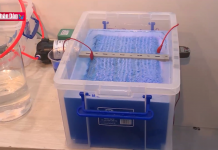

Experts of VinIT Institute of Technology have made inventions and improvements to overcome the disadvantages of this technology by the following methods:

- Increasing the capacity of Plasma torches to 500 kW (VinIT plans to research for a capacity of over 1000 kW) and lifespan to over 2000 h (2-3 times more than other torches of the world);

- Reduce the cost of designing, manufacturing and commercializing Plasma torches;

- Redesigning Plasma reactors to optimize process gasification, increase Syngas production;

- Using Syngas gas for electricity generation, ensuring a positive coefficient of electrical energy up to 30-50%.

- Technical improvements allow the investment rate to be lower than the world’s Plasma technology, even lower than the investment rate of other gasification technologies and lower than the investment rate of the conventional combustion technology. As a result, the payback period is only 6-10 years compared to other technologies from 15-20 years.

Experimental specifications and index calculations of domestic waste in Hanoi and Ho Chi Minh City show that Plasma gasification technology with VinIT’s innovations is perfectly suited to waste treatment in Vietnam. Ensured not only technical and environmental requirements but also investment and profit parameters. Especially, VinIT is completely proactive in technology, equipment and experts needed to carry out these technology projects in Vietnam.