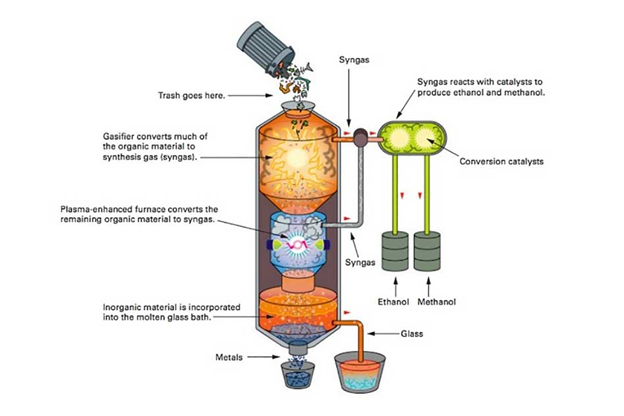

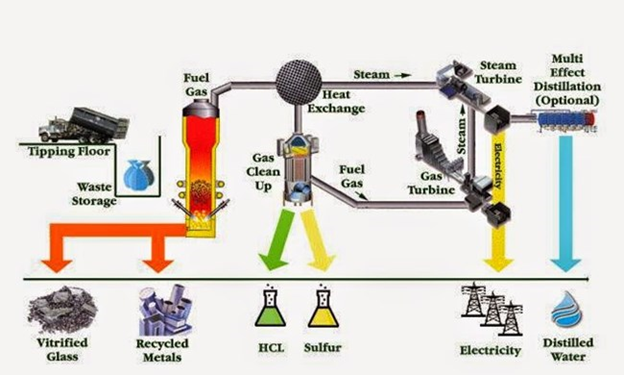

Plasma gasification is a process which converts organic matter into synthetic gas, electricity, and slag using plasma. Inside the gasifier, the hot gases from the plasma torch or arc contact the feedstock, such as municipal solid waste, auto shredder wastes, medical waste, biomass or hazardous waste, heating it to more than 3,000 degrees Fahrenheit.

This extreme heat maintains the gasification reactions, which break apart the chemical bonds of the feedstock and converts them to a synthesis gas (syngas). The syngas consists primarily of carbon monoxide and hydrogen—the basic building blocks for chemicals, fertilizers, substitute natural gas, and liquid transportation fuels. The syngas can also be sent to gas turbines or reciprocating engines to produce electricity, or combusted to produce steam for a steam turbine-generator. Plasma gasification uses extremely high temperatures in an oxygen-starved environment to completely decompose waste material into very simple molecules in a process similar to pyrolysis. Because the feedstocks reacting within the gasifier are converted into their basic elements, even hazardous waste becomes a useful syngas. Inorganic materials in the feedstock are melted and fused into a glassy-like slag, which is non-hazardous and can be used in a variety of applications, such as road-bed construction and roofing materials. It is used commercially as a form of waste treatment and has been tested for the gasification of biomass and solid hydrocarbons, such as coal, oil sands, and oil shale.

- The feedstock for plasma waste treatment is most often municipal solid waste, organic waste, or both;

- Plasma processing of waste is ecologically clean;

- The lack of oxygen prevents the formation of many toxins;

- The high temperatures in a reactor also prevent the main components of the gas from forming toxic compounds such as furans, dioxins, NOX, or sulfur dioxide;

- Water filtration removes ash and gaseous pollutants;

- The production of ecologically clean synthetic gas is the standard goal;

- The gas product contains no phenols or complex hydrocarbons;

- A portion of the syngas produced feeds on-site turbines, which power the plasma torches and thus support the feed system. Thus this is self-sustaining electric power.

The Main Ecological Benefits of Plasma Gasification

Plasma gasification provides a number of key benefits over incineration systems:

- It unlocks the greatest amount of energy from waste;

- Feedstocks can be mixed, such as municipal solid waste, biomass, tires, hazardous waste, and auto shredder waste;

- It does not generate methane, a potent greenhouse gas;

- It is not incineration and therefore doesn’t produce leachable bottom ash or fly ash;

- Clean destruction of hazardous waste, preventing it from reaching landfills;

- It has virtually no harmful environmental emissions;

- Production of clean alloyed slag which could be used as construction material;

- Processing of organic waste into combustible syngas for electric power and thermal energy;

- Production of value-added products (metals) from slag.

A Plasma Power Plant can also utilize existing landfill content as a feedstock, thus cleaning up previously toxic sites and enabling them to be sold for other uses such as development. For those conscious of the need to cut their carbon footprints, its carbon contribution to the environment is virtually nil.

Analysis of the Plasma Gasification process has been shown to have a ‘negative’ carbon footprint in comparison to other forms of energy generation, produce virtually zero emissions and has the highest landfill diversion rate of any available technology, making it very attractive to local authorities. While plasma technology has been in use for many years it has only recently been developed as a waste management solution.

This was partly because the conventional landfill approach was considerably less expensive, even with transportation costs and gate fees, and there was no regulated requirement for low-carbon energy. However, with increasing landfill diversion targets and renewable energy targets, the relative cost of the technology has been transformed.

The Main Financial Benefits:

An average plant using 100,000 tonnes of MSW could generate six steady revenue streams from each site:

- Tipping fees for the waste it receives;

- Sale of any recyclables removed;

- Electricity generated (sold to the local grid on long-term power purchase agreement);

- Heating or cooling sold to local companies, eg hospitals, offices;

- Double ROCS under the UK Renewable Obligation scheme; (if in UK, other countries may have similar schemes);

- Sale of the glassy by-product, produced by the process and sold as building material.

Resource: utagtechnology.com