Plasma is the state of matter obtained by breaking down atoms into ions and electrons by the process of ionization. Plasmas can quite easily reach temperatures of 10,000 degree Celcius.

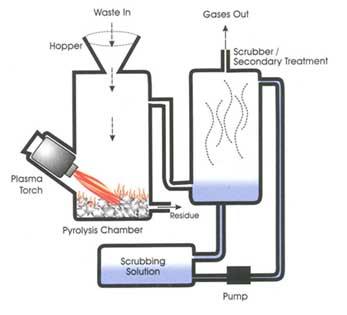

Plasma technologies offer unique solutions to meet the increasing demands of dematerialization to develop ecologically sensible industrial practices like high temperatures, high chemical reactivity, high energy density and ability to process solids, liquids and gases. In plasma pyrolysis, generation of heat is independent of chemistry of material used. It is fast heating – 5000 Celcius can be achieved in milliseconds. It is fast quenching and consumes small quantity of gas. The high ultraviolet radiation flux destroys pathogens and waste to be treated, could be dry or wet. It is possible to recover energy in the form of carbon monoxide and hydrogen.

The Facilitation Centre for Industrial Plasma Technologies (FCIPT) of the Institute of Plasma Research, Gandhinagar, Gujarat, an aided institute of DAE, has developed Pyrolysis System for disposal of medical waste. The unit is operating at the Gujarat Cancer Research Institute at Ahmedabad and the technology has been transferred to a private entrepreneur M/s Bhagwati Pyrotech Pvt. Ltd., Ahemdabad, Gujarat.

Plasma pyrolysis provides solutions for complete pyrolysis of typical hospital waste such as cellulose polymer dressings, polyvinyl chloride blood bags, polyurethane and silicon rubber gloves & catheters and other disposables made of polyethylene, polymethyl methacrylate, rubber, glass etc. The system provides high temperatures combined with high UV radiation flux which destroys pathogens completely.

For the safe disposal of medical waste, FCIPT of the Institute for Plasma Research has developed a Plasma Pyrolyser which incinerates waste using plasma technology.

Technical Brief of Plasma Pyrolyser

Plasma Pyrolysis System incorporates “CASS” (Complete Automated Safety System) that ensures an operating environment, which exceeds any safety norms.

The cost of installing, operating and maintaining the Plasma Pyrolysis System is on par with conventional incineration facilities of similar capacity.

The inherent simplicity, lack of moving parts, system redundancy, automation, and proven stability of the Plasma Pyrolysis System ensure very high reliability with minimal downtime and maintenance requirements.

Electricity requirement is very low. It is less than 1 kWh per kg of charge (approx.). With the exception of start up and shut down, the plasma field is normally sufficient to maintain operating temperatures. With the additions of oxygen generators and co-generation, operating cost are well below and conventional waste processing or energy production systems in the market today.

The Bio-Medical Waste Disposal System is under actual field trials at the Gujarat Cancer Research Institute, Ahmedabad since August 2001. It has been operated for disposal of infected bio-medical waste including plastics, cotton, pathological waste and tissues. The waste is treated for disposal as collected from the hospital without any segregation or pre-treatment. The system was run on a continuous basis for 4 to 5 hours per day. The rate of disposal was 18 – 20 kg/h. In December 2001, the system was tested for more than 100 hours for various combinations of waste material and operating conditions. More than 500 kg. of infected bio-medical waste was treated. The system was run exclusively for treated human tissues and pathological waste. During trials 100 kg of tissues were treated. The System is microprocessor controlled, allowing one individual to operate one processing reactor systems, including loading and temperature controls.